Guide for HVAC Duct Shop Drawings: Convenient HVAC duct shop drawings constitute an essential part of any detailed heating, ventilation, and air conditioning (HVAC) design documentation for new buildings or retrofit installations.

This article will discuss what HVAC duct shop drawings are, why they are essential to the design and construction process, and how to draw them correctly for successful project commencement and completion.

Understanding HVAC Duct Shop Drawings

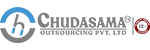

HVAC Duct shop drawings are detailed drawings that show duct layout drawings in the buildings. They serve the purpose of planning and installing HVAC systems and are essential for ducts, vents, and system component visual arrangements.

These drawings reduce the chances of incorrect installation, maximize airflow, and ease maintenance and repairs. They ensure correctness, improve performance, and increase energy efficiency for the work of HVAC technicians as well as contractors.

What are HVAC Duct Shop Drawings?

HVAC shop duct drawings are comprehensive duct layout drawings that are used for the design and installation of HVAC systems. They are usually graphical images generated by a CAD program and show the HVAC layout as seen from above in the building. These types of drawings are beneficial in different phases, from planning to construction and installation.

Different Types of Drawings

Plan Drawings: These provide an aerial view of the ductwork drawing and its integration into the structure of the building.

Elevation Drawings: These provide a visual perspective from horizontal and vertical planes in the perspective of ductwork drawings within the building.

Section Drawings: The cross-sectional views are applied to highlight the particular components of the ductwork, including insulation, inner liners, dampers, etc.

Detail Drawings: These are exquisitely detailed close-up drawings of specific ductwork drawing details (also known as enlarged details).

Also read: 46 Types of Drawings Commonly Used in Design and Construction

Components of a Typical HVAC Duct Shop Drawing

- Title Block and Project Information: Establishes the venture, its location, and the key stakeholders involved.

- Sheet Details: Note the number of the sheet and the total number of sheets in the drawing.

- Scale and Graphical Representations: This provides a reference for duct size in the facility.

- Keyed Components: To simplify identification referencing.

- Legends and Symbols: This naturally facilitates the comprehension of several design-related aspects.

- Design Data: This includes the flow rate, pressure classes, velocity, and equipment specifications.

Definition and Purpose

The function of HVAC duct shop drawings is to translate the conceptual design into the final design that can be used for manufacturing and installation of the HVAC system. They resolve complexities that may occur and guarantee that all parts fit within a targeted structure and are optimized for operation.

Key Components of Duct Shop Drawings

These are ductwork dimensions, material type, location of branch points and their size, support placements and various duct routing details, notarized by dimensions and flow indications to show final air direction.

The Role of HVAC Duct Shop Drawings in Construction

In construction, HVAC duct shop drawings services are of great importance since they help in organizing and executing HVAC system installation.

These drawings serve as a communication tool for architects, engineers, HVAC specialists, and construction workers. They give a plan of ductwork installation that corresponds with the design of the building and results in the smooth incorporation of the HVAC system.

This integration is crucial for today’s energy-efficient and space-saving projects. How Shop Drawings Improve the Communication Between the Stakeholders.

The shop drawings are mostly shared among the HVAC design team, architects, structural engineers, and other project stakeholders in order to ensure that every detail of the system is planned and counted. They are a universal language that all parties can understand, and this prevents miscommunication and costly mistakes.

Building Codes and Regulations

The primary purpose of shop drawings is to verify that the HVAC system was designed to comply with local building regulations and codes. Adherence from the start eliminates possible problems in the end.

Streamlining the Construction Process

Accurate and well-detailed shop drawings will help to bring about a smooth construction process by establishing clear installation guidelines. The time and materials spent in correcting the mistakes will be significantly minimized due to the elimination of the guesswork.

Benefits of Accurate HVAC Duct Shop Drawings

Accurate HVAC duct shop drawings offer several tangible benefits that contribute to the efficiency and success of construction projects.

Accuracy

Experts indicate that correct drawings are associated with a reduction in reworking and faster construction. They are the most accurate and help us make and install them as per our design specifications.

Improved Communication

A frequent reason why project delays and disputes arise is poor communication. Properly arranged shop designs increase clarity by allowing all parties involved to appreciate an illustrated reference, which descriptions only cannot do sometimes.

Streamlined Installation Process

Given all the preparation information available, the installation procedure can progress smoothly. The very same detailed drawings serve the purpose of co-coordination with other trades, such as the electricians and plumbers who have to work together with the HVAC system.

Compliance with Codes and Regulations

The consequence of non-compliance can be grave, ranging from the levying of a fine to having to rework a significant part of the project. Such support drawings can also help project managers deal with regulatory compliance.

Cost Savings

Reduced errors and a more efficient construction process will lead to cost savings in the project. If the drawings for the duct shop are precise, the systems will be energy-efficient, which will provide the building owner with long-term benefits.

Software Tools for Creating HVAC Duct Shop Drawings

Nowadays, in the digital age, drafting HVAC duct shop drawings is simplified with tools that are specially made for drafting. These apps result in accuracy and productivity enhancement because they auto-done some tasks. Some popular tools include:

AutoCAD: A mainstay of the industry, called AutoCAD, helps to create detailed drawings of 2D and 3D designs. Such a crucial feature as availability anywhere and for all users makes it a powerful tool for sharing information across different entities.

Revit: Influenced by its advanced BIM (Building Information Modeling) features, Revit allows you to do complete modeling of your HVAC systems, thus helping you integrate better with other building systems.

SolidWorks: Primarily based on 3D solid modeling, SolidWorks provides specific design-and-analyze tools for HVAC systems with a primary goal of both performance and compliance.

MagiCAD: Specially made for MEP (Mechanical, Electrical, and Plumbing) design, MagiCAD automates most of the complex algorithms needed in HVAC systems and in this way, the design process can be redone in much faster time.

Each of these tools possesses specific distinct characteristics and functions, and the choice between them largely depends on the particular requirements of the project, the favorite selection of the design team, and compatibility with the work procedures of the other professionals working on its construction—Specialized Tools for Fabrication of the ductwork drawing.

Best Practices for Creating HVAC Duct Shop Drawings

Creating HVAC duct shop drawings follows a meticulous and detailed approach to ensure efficiency, compliance, and ease of installation. Here are some best practices to consider:

Utilizing CAD Software

Choosing the right CAD software and becoming fluent with the tools and functions can be the key to success. This also involves keeping yourself updated on the latest versions as well as learning how to automate the repetition task.

Following Industry Standards

HVAC engineers should adhere to ASHRAE (American Society of Heating, Refrigerating, and Air-Conditioning Engineers) standards as well as other design guidelines in order to produce functional duct designs that are also ASHRAE compliant.

Collaborating with Stakeholders

Close working relationships with all the project’s participants throughout the process enable all shop drawings to be correct and in line with the agreed design and structural and regulatory considerations.

Incorporating Feedback and Revisions

The feedback review process, as it is, is an integral part of the shop drawings development. It assures that the final document will be genuinely effective.

Challenges in HVAC Duct Shop Drawings

Creating HVAC duct shop drawings for construction schematic drawings for construction projects brings up challenges; however, they are still outstanding. It is a significant obstacle to drawing a precise image of real-life scenes, even with modern computer applications.

Common Errors to Avoid

The lack of efficient spatial coordination, accurate material and dimension specifications, and adequate labeling can result in serious difficulties later on.

Changes in Design

For instance, one of the problem areas is the integration of design changes. When revisions are needed, shop drawings must be revised and communicated accurately in a manner to make sure a quality project is being completed within the expected timeframe.

Time Constraints

Determining the right level of detail while keeping projects on schedule is one of the critical factors. Hurrying the shop drawing process is the main reason for avoidable mistakes, but the fact that taking too much time can delay the project is a critical factor.

Ensuring Compliance with Regulations

It goes without saying that keeping up with the newest building codes and regulations is an everyday task. HVAC technicians are pretty much forced to keep learning and changing with the altering requirements.

Why Choose Our HVAC Duct Shop Drawings?

Chudasama Outsourcing offers shop drawings services for HVAC, sprinkler systems, and piping fabrications. Our team of HVAC shop drawings experts are able to view all the duct branches, cut duct length, duct, and pipe insulation thickness, etc., and this will enable you to get professional and precise drawings done by our ductwork and plumbing shop drawings department to complete your project.

Chudasama Outsourcing Over the years, we have served clients in the US, UK, Canada, and Australia, providing them with HVAC shop drawings.

We are focused on the long-term relationship between our clients and our business, which is based on the high-quality HVAC, Piping & Plumbing Shop Drawings. Our HVAC Duct Piping Shop Drawings and HVAC Duct, Fabrication Shop Drawings, are precise to a high degree.

Notwithstanding, we do not require the CAD or PDF files of your Structural, Architectural, and reflective ceiling plan, size of insulation, cut length of ductwork, heat exchanger, and ventilator. The office will do the HVAC Duct Coordination Drawings for your projects as well.

The drawing for the HVAC system shows detailed plans for ventilation, the circulation of air within the building, and thermal distribution from one point to another inside the building. Knowing a drawing plan definitely eases communication and planning. Experts within our organization will be able to develop HVAC shop drawings for company standards.

Conclusion

HVAC duct shop drawings are as important as the HVAC systems they represent. By following the comprehensive guidelines laid out in this post, HVAC professionals can create drawings that not only fulfill a regulatory and communication function but also contribute to the overall success of a construction project. It’s a meticulous process, but one that pays off in the functionality, efficiency, and cost-effectiveness of an HVAC system in the end.