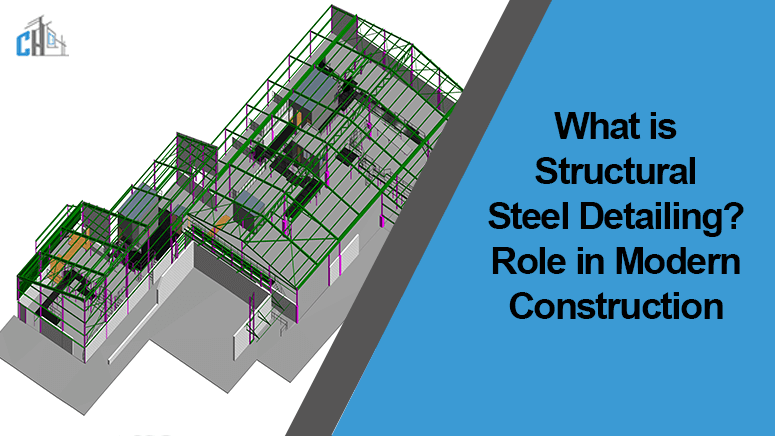

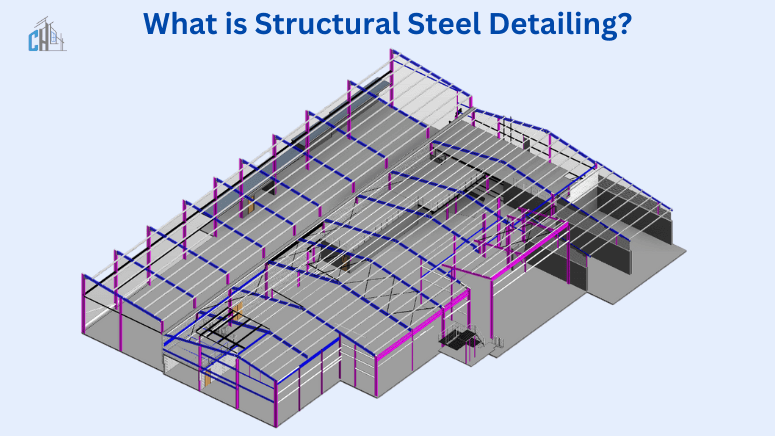

Quick summary: Structural steel detailing is a critical process in modern construction, where detailed drawings of structures are produced to be used by steel fabricators as well as erectors. In architecture, these drawings provide mechanics and architects with directions on how to go about constructing the desired structure perfectly and safely to meet the engineering drawings.

Structural Steel Detailing in the contemporary construction industry is a vital function in the architectural development of today’s furious skyline.

This is not just a technical exercise; it is a form of sculpture that takes basic materials and transforms them into impressive structural frameworks for our buildings. Because the construction industry focuses on the aspects of precision and efficient delivery of structure, there is no doubt that learning about structural steel detailing is crucial.

This blog post will simplify the complexities of steel detailing, its crucial role in construction, and the technologies propelling it forward. Its importance in construction and advanced technologies promoting the field. For anyone who is an architecture, engineer, or construction professional it is crucial to understand the complexities of structural steel detailing to remain relevant in the construction industry.

What is Structural Steel Detailing?

Fundamentally, structural steel detailing deals with preparation of Structural Shop drawings for installation of structures. These drawings are plan sheets that display detailed cutting and fabrication sequences of steel members.

It begins with architectural and engineering drawings translated from highly detailed blueprints understandable to architects and engineers into those possibly actionable on the construction site.

Primary parts of a detailed model are the designs of, literally, any part of the steel skeletal structure including columns, beams, connections, reinforcements, etc. Each output is accompanied by information on where each part belongs in the structure and the material grade and size of each part.

The detailing process aims at preventing poor communication between designers and constructors, hence it brings out the best in the project.

The collective needs of this process are detailed outputs supporting construction projects through accurate fabrication and erection of steel. As such, this form of precision cuts on wastage of materials, makes it safer to work on a construction and guaranty that the final construction is as per the plan.

Also read: Your Go-To Guide for Structural Steel Detailing Services

The Role of Structural Steel Detailing in Modern Construction

Today, it is impossible to imagine the construction of modern buildings without structural steel detailing. It serves as a mediator between architectural and engineering designs on the one hand and construction realities on the other. Usually, the detailed models help construction professionals to visualize the potential problems, thereby improving project performance.

Another advantage of structural steel detailing is improving the efficiency of the project. Detailed models ensure that there are limited changes made on site, for they help in planning, and thus there are likely to be minimal constructions alterations that would end up incurring more money.

In addition, it enhances interorganization teaming as it provides an integrated approach that proves useful to architects, engineers, and fabricators.

It is also important for defining lots of styling cues for the vehicle and for determining safety and structural factors. Correct models do not allow for misalignments and flaws in structural design that might endanger a building.

It is an anticipatory measure in construction that not only improves safety but also guards structures against normal wear and tear in the environment.

Looking to Outsource Your Structural Steel Detailing Services? Reach Out to Us Today for Expert Solutions!

Tools and Software Used in Steel Detailing

Structural steel detailing has undergone a significant change in the development of technology as pointed out in the following. Today’s professional requires a set of refined instruments and applications to improve precision and productivity.

Software like Tekla Structures, AutoCAD, and SDS/2 consist of strong frameworks to build complex steel designs. These tools have features such as model based on 3D, automatic creation of details, or BIM system compatibility.

Such tools have come along way in changing the face of construction. Where before drafting was done by hand the software now provides for models which can be quite flexible for a changing project scope. This flexibility comes in handy, especially in an industry where deadlines and requirement standards are flexible.

In addition to increasing precision, these tools promote increased cooperation. The fact that all the tools are shifted to the cloud allows for timely monitoring and updates to keep all stakeholders on the same page across the project delivery phase. This level of synchronization minimizes incidences of mistakes and Fridges project to run as planned or expected.

The Future of Structural Steel Detailing

Further on, the perspective of the structural steel detailing shows even higher possibilities of development. Other advancing tendencies, including AI and machine learning, are expected to increase detailing accuracy further. These technologies can anticipate matters of concern before they occur, providing preventive strategies to human beings thus reducing costs and time.

Another emerging area is application of augmented reality in the construction phase of projects. AR can import both detailed construction design and precisely impose it on the construction zone providing the construction workers the vision of where and how the steel components need to be place. This kind of invaluable tutoring minimizes pitfalls on site and improves precision.

Over time, probably all these technologies will form part of the detailing Process of Structural Design of Building as these technologies become more developed. Any professional who is able to update themselves with these advancements will be in a position to practice in an otherwise more complex profession that will be able to deliver both efficiency and elegance in terms of architectural designs and construction.

Best Practices in Structural Steel Detailing

The need to maintain efficiency and accuracy for those in the structural steel detailing field can’t overemphasized hence the reasons to adopt best practice in the field. To begin with, there is always a need to have a good rapport with all those affected in the organization.

This eliminates situations where some individuals, for example, the architects, have a different perception from the fabricators or where different people are offering different solutions to the same problem.

Another is care in detail, to be very particular about the work that you do. The authors pointed out that even a small difference in detailing may result in major problems during fabrication and construction. Conducting quality assurances and control activities in the midst of detailing can help identify mistakes before the final stage and recheck that the final product meets project requirements.

Finally, training and capacity development are important in order to incorporate new technologies and methodologies into practice. Structural detailing as a field is not stagnant at all, and structural steel detailers who actively seek, maintain, and apply new tools and methods can improve their ability and results drastically.

Outsource Structural Steel Detailing Services and Make the Most of Technology

At this time, in a highly competitive industry, outsourcing structural steel detailing services can be useful. By affiliating with firms with rich detailing experience, the knowledge of detailing experience brings in applicability of industry expertise and advanced technologies that integrating firms would otherwise cannot afford to develop in-house.

Many of these service providers usually have staffs whose work is to update themselves with modern trends as well as practices in this field, meaning that your project will certainly derive great benefits from such practices. Outsourcing also saves time and efforts for construction firms to concentrate on their strength, while they let skilled persons have the responsibility of accurate steel detailing.

By leveraging outsourced detailing services, businesses can also scale their operations more effectively. With a trusted partner handling the detailing, companies can take on more projects simultaneously without compromising on quality or timelines.

Conclusion

Structural steel detailing is undoubtedly one of the most significant aspects of construction at the present. As the physical world’s link to the conceptual world, it translates architectural designs into usable frameworks that minimize wasted effort, time, or resources while maximizing safety on project sites. As construction professionals, the increased detailing practices and technologies require one to update himself or herself in order to remain relevant.

The detailing process can be optimized in a very extensive way by integrating various techniques, using better technologies, providing Structural steel detailing services with the help of outsourcing services, and using up-to-date tools and techniques.

Therefore, professionals can apply their ideas for the initiative of projects, which will conform and surpass normative standards. In light of this, one should hire the current tools, try to get to attend the various workshops within the building industry or get to talk to peers who can help them to update their ways of dealing with structural steel detailing.