Welcome to the Ultimate Construction Shop Drawings Guide for 2025! In this comprehensive guide, we will cover everything you need to know about construction shop drawings and why they are crucial in the building process.

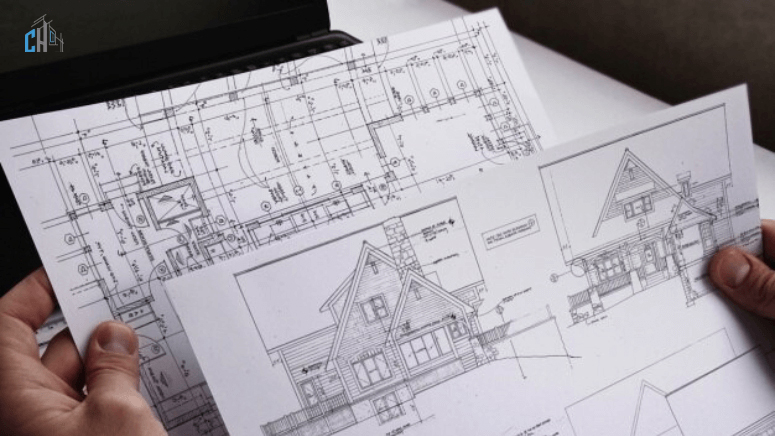

Construction Shop Drawings: In the intricate tapestry of the construction industry, where precision and foresight become the triumph or defeat of a venture, the shop drawings become the silent hero that smoothly translates the blueprints into concrete reality.

Architects, Engineers, and Construction Managers realize the importance of precise and correct shop drawings for reducing processes and work and preventing costly errors. Through detailed descriptions and illustrations, readers can understand every side of construction shop drawings.

This guide will show everyone why these drawings are so important, the different types of drawings, the upcoming challenges, and how exactly these drawings will be used in the future.

What Are Shop Construction Drawings?

Shop drawings are detailed plans and diagrams that tell the workshop everything they need to know about building, assembly, and installation of each component in all aspects of construction projects. Unlike a preliminary or a contractual agricultural template, they illustrate details of specific components (materials, dimensions, and processing instructions) that the manufacturers and contractors follow.

They can be explained as a roadmap to manufacture and assembly, where all pieces are fitted well into the project’s overall design. The drawings were contributed by helping the designers, as well as the fabrication and on-site construction staff, to communicate briefly. As a result, misinterpretations and mistakes are minimized, and time and resources are appropriately utilized in the construction processes.

Why Are Construction Shop Drawings Important?

Before shaking hands on what and why, shop drawings should be examined; they are an essential part of construction work.

The shop drawings are detailed drawings generally prepared by tinsmiths, iron workers, and metal fabricators for areas covering elevator systems, air handlers, and steel structures. These drawings are essential for several pivotal reasons: These drawings are necessary for several key reasons:

Detailing Project Specifications: Unlike the general contractor’s working drawings, which are designed for a better-generalized view of the project, shop drawings focus on the specific dimensions, materials, and installation details for the end product in a particular project.

Meeting Compliance and Safety Standards: The contractors’ shop drawings guarantee the project adheres to all local regulations, including safety standards that are essential for getting approval for construction and eventual usage.

Aiding in Visualization: Highly mapped, these drawings help stakeholders visualize the finished product not only in a rough way but in great detail therefore, they have an opportunity to make the adjustments and confirmations before construction starts.

Enhancing Communication: They help establish uniform communication between the various departments and team members, ensuring that everyone is aligned with the master plan of vision and execution.

Types of Construction Shop Drawings

The shop drawings construction industry is simply trying to keep up with the fabric of the trades and its many facets. Here are some of the most common types you should be familiar with: Here are some of the most common types you should be familiar with:

Architectural Drawings

Architectural shop drawings are self-contained documents that translate the design text of a building into a tool displaying current and future views and other functional elements as shown in the architectural blueprints. They present information on all of this, from the floor plan to the section/elevation and the site plan.

Structural Steel Shop Drawings

This series gives directions for the setting up of steelwork, mainly using welding or bolting techniques to achieve a desired shape.

They are offices mainly for construction contractors, where they provide details such as plans and elevation along the section. From these different views, builders can find, for example, dimensions as well as structural members and how best they can be set appropriately.

MEP Drawings

MEP drawing specializes in the building’s mechanical, electrical, and plumbing systems. As a technician, I am involved in the installation and maintenance of complex systems, such as HVAC, plumbing, and electricity systems.

They give not only a comprehensive outlook of the part pre-booted items and the construction process requirements but also a rundown of the services offerings and their different unique features.

Façade Shop Drawings

Facade drawings are mostly related to the building’s external façade sheet illustrations, and they are done for the minor detailing of windows, curtain walls, and cladding systems. They are essential for the beauty and structural functions of the city thus, they play a massive role in the life of the city.

Assembly Drawings

This follows with detailed drawings of how various units will be assembled and function as a complete unit, whether it is a mechanical assembly, HVAC unit or a complex machine.

Millwork Shop Drawings

The millwork drawings service is the basis of these elements ‘ fabrication when it comes to custom details, like cabinets, doors, windows, and architectural casework.

Glazing Shop Drawings

The glasswork detailing is critical for buildings where glazing shop drawings are a must. Here, the drawings elaborate on the types and installation details of glasses, frames, and supports.

Also read: 46 Types Of Drawings Used In Design & Construction

Critical Components in Construction Shop Drawings

A successful shop drawing is a harmonious assembly of several vital elements that ensure clarity and comprehensiveness. A successful shop drawing is a balanced assembly of several vital elements that provide clarity and comprehensiveness:

Scale, Dimensions, and Details: Through the correctness of scaled-down figures and dimensions, the builders can have a pretty convenient plan which they can use to calculate the materials needed for the structures.

Material Specifications: Material types and some particulars — like the finishing of a light fixture — of a shop plan will indicate where the materials can found and their attributes.

Symbols and Legends: These elements decode the pattern so that installers and other actors have their instructions, avoiding mistakes and errors in the work process.

The Importance of Accurate Shop Drawings

The shop drawing may need to be more accurate because it will cause a chain of costly consequences like time overruns and safety hazards. Here’s why accuracy is non-negotiable: Here’s why accuracy is non-negotiable:

Enhanced Communication: When a situation in which all the stakeholders employ precise and synchronized data comes about, the possibility of misplacing one’s message or mixing signals with other people will be as minimal as possible.

Project Accuracy and Efficiency: Accurate shop drawings, in turn, lead to precise construction, which leads to both a timely and successful building process and cost.

Error Mitigation: Spotting discrepancies between shop drawings and project designs promptly makes it possible to take corrective measures. This increases effectiveness and saves money that would have otherwise been require in rework.

Tips for Creating Effective Construction Shop Drawings

To ensure your shop drawings are as effective as possible, follow these actionable tips:

Advanced Software Tools

They are saying adios to those days when hand-done drawings for shops were painstakingly made. Nowadays, the design of different industrial software tools accelerates the drawing job and provides highly complex detailing and collaborative tools to their users.

Collaboration and Feedback Processes

Constant exchanges among team members and stakeholders engaged in shop drawing development ( the different teams and individuals directly involved with the meaningful translation of architectural plans into works) are needed for everyone to be involved and to deliver plans that are by project relief.

Quality Assurance

Set up thorough review and approval procedures so that all the bugs and mistakes can be check before the drawings are approved, ensuring that all rules and what needs to be built are accurate.

The Future Of Construction Shop Drawing

The rapid advancement of technology will lead to a promising yet challenging future for construction shop drawings. Integrating prefabricated design, using the latest BIM (Building Information Modeling) software, and adding AI-powered solutions are all expected to reshape the field.

These up-to-date changes demonstrate the growing significance of detailed drawings in making project processes smoother and more efficient.

Why Opt for CAD Drafting Company for Your Shop Drawing Projects?

CAD drafting, one of the leading global providers of shop drawings services, stands out for its unparalleled reliability and superior quality in construction shop drawings. Their team of specialists, who can offer a wide range of expertise, ensures that each project will aided by the participation of the most efficient and accurate drawings, contributing to the success of all their projects.

Conclusion

Construction shop drawings are an essential part of construction that constructs reality. Their effect cannot underestimated, from how they affect the day-to-day operations to how they envision the industry’s future. By comprehending the complex details of the shop drawing services in construction, you will guide your construction projects to success, efficacy, and safety.