The construction and design in the building end of the world in which precision is an indispensable component. From towering high-rises that puncture the skyline to the most minute of interior design pieces, drawings are the spark for creative flow, which ignites the project into reality.

The bridging role in this blueprint-to-reality is played by fabrication drawing, as it is the stage where architectural design transitions into actual physical construction. We’ll cover the types of fabrication drawings and their utility in reliable project management starting from this comprehensive article.

An Overview of Fabrication Drawings

Fabrication drawings are technical illustrations and diagrams that envisage more detailed specifications and instructions required for the building or manufacturing of a part, hence structure.

They are commonly developed after the design phase based on the construction documents and utilized by fabricators, assemblers, and contractors to undertake production of the project to match the design accurately.

The Journey from Idea to Implementation

From the intricate designs of bridges to the technology the smart homes depend on, the extraordinary conversion of these detailed drawings to reality is the skill of excellent fabricators.

The blueprints, therefore, translate the design’s mathematical and technical data into terminology that the lay audience can understand so as to be the door for the project physics.

What are Fabrication Drawings?

A detailed fabrication drawing is a crucial document in the construction process, providing a pictorial representation of envisioned structures.

It is thoughtfully designed to assist builders in building their projects accurately and to the correct precision level at all times. To fulfill the purpose successfully, the drawing must be concise and informative, including, among the other items, all the sizes and details of the construction in use necessary for the realization of the project.

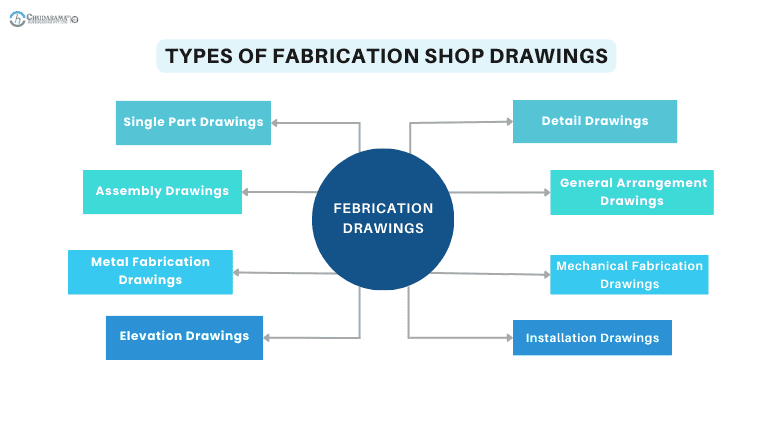

Types of Fabrication Drawings

Construction drawings come in different forms, each of which contributes a unique function to the construction process. Here, the illustration represents several of these drawings of art and how they are combined with the above.

1. Single Part Drawings

A one-part drawing is, in other words, something whose design shows exactly—it is used to display the characteristics of a specific part or a component.

In these drawings, one object at a time is taken into account; the sizes measured on the plan, the appearance at the cross-section, and the rest of the information are defined. Because they provide the necessary infrastructure for the crafting of individual parts, they are significant in ensuring the correct production of the components.

2. Assembly Drawings

Assembly Drawings show how separate elements of a set of related individual parts, usually more than one, come together and function as one single compound unit or product. These drawings are the primary picture of the parts and their connections; therefore, it is mandatory that the process of assembling will be done correctly and quickly.

3. General Arrangement Drawings

General arrangement drawings play the role of outlining the design and show the possibility of witnessing the project as a whole. Starting from the basic model including dimensions and structural details they will make an excellent job during the planning stage and when the concept is approved.

4. Mechanical Fabrication Drawings

Mechanical fabrication drawings are a type of drawing that bears special meaning regarding the mechanical aspect of the project, which may be the HVAC system itself or machine components integrated into a structure. These are vital issues for ensuring that all mechanical part is make correctly and remain correctly.

5. Metal Fabrication Drawings

Metal fabrication drawings are in-depth representations of metal components that are to fabricate as per the given instructions. They are utilize in metal fabrication, ranging from the production of structural steel in buildings to exquisite intricate metalworks in high-profile designers’ projects.

6. Elevation Drawings

Elevation drawings are shown from a specific direction or point of view and are flat, which means the drawing is not in perspective. These are, therefore, crucial in understanding the project’s visual effects and whether or not the components suit their places within the community.

7. Detail Drawings

Annotated drawing gives more details about the subject depicted. They may either highlight crucial parts with callouts, identify them as parts of the joints, and uphold the structural integrity of the design.

8. Installation Drawings

It is not just that installation drawings are there to show the structure, but installation procedures as well. This comprises the details of staging, info on orientation, and what component goes first and second. These illustrations are necessary to ease the process of installation and achieve the desired performance.

Also read: Types Of Drawings Used In Building Construction

Importance of Fabrication Drawings

Fabrication drawings are the base of many aspects that are tied to the building utility and safety indices, which, in turn, determine the quality of construction. Below, you will find the basic but the most important things where the construction drawings are, such as the cornerstones of the projects for construction.

Ensuring Quality and Consistency

They, being the legislative, the senate and the consuls, play a role in creating quality and standardization requirements. The latter have to meet by every component. The achievement of this results in a final product that guarantees consistency and quality. Such quality proof is essential for safety and longevity.

Legal and Environmental Compliance

Today’s prevailing construction environment unavoidably requires fabrication documentation to enable compliance with the local building codes, environmental standards, and any other relevant regulation framework.

Cost Estimation and Control

Having an accurate numerical transfer of projects is invaluable for the estimation of cost and financial requirements. It causes the preparation of budgets that put all estimations close to the mark.

Benefits of Fabrication Drawings

Structural steel fabrication drawings used in projects present multiple positive features as that enhance the results and the project flow. Take a closer examination of this than the advantages from which you can expect to see by investing in detailed fabrication drawings.

Improved Communication and Coordination

Precise drawings with clear details assist in gatherings of owners, architects, technicians, suppliers, and contractors. Of course, the shared knowledge of the project specifications significantly reduces the area of misinterpretation and helps explain collaboration.

Enhanced Precision and Efficiency

Fabrication drawings nearly ensure they comprise the lack of no mistakes. They give exact measures and specifications, and therefore they could use to manufacture some minute parts for the larger structure with undisputed accuracy. Proper planning ensures effective work processes are use, while the result ends up meeting the project specification.

Cost Savings and Risk Mitigation

The main effect of fabrication drawings is the reduction of errors and the process of changing design instructions during construction, which will result in dramatic cost savings. Furthermore, this art might assist auditors in spotting risks at the early stage of the project for preventive action.

Compliance and Quality Assurance

Fabrication drawings address the main concern related to the actual construction performance as compared to the industry standard. In addition, they serve as the building blocks of quality assurance protocols, which classify every component into multiple criteria.

How Fabrication Drawings Benefit Your Project

An accurate and detailed design build drawing is what the best project success is compose of, as these drawings must play a decisive role in the final resolution. Bearing in mind that drawings do not exist in a vacuum but play a prominent role in your project’s progress and completion, retaining a fundamental knowledge of these drawings is essential.

Streamlined Workflow

Fabrication drawings are where the real magic happens. They provide a plan and guide the fabrication and installation processes. When all here is in place and working together, the output path remains consistent, and the workflow is disharmonizing with a clear direction forward.

Reduction of Rework and Errors

Most importantly, agreement on the same document and rational drawings can help reduce the amount of reworking and, thus, errors. Through the integrated approach that comprises the initial stages of construction, the risk of on-site revisions of already-built structures is decrease.

Enhanced Collaboration Among Stakeholders

The process of developing and using fabrication drawings calls for solid teamwork between all stakeholders of the project. It creates an environment where the sharing of ideas, problem-solving, and the development of best working practices can do, and these can draw on other future projects.

Also read: The Top 7 Compelling Reasons to Outsource Shop Drawing for Your Projects

How to choose Chudasama Outsourcing for Fabrication Shop Drawings Service

Fabrication drawings provide the manufacturing authority with a standard guideline to ease the construction process by avoiding complexities. Sourcing the highest fabrication shop drawings from a company that is recognized for its high-quality products is rewarding in a number of ways.

It fosters the efficient process of building up and helps to save much more resources than is need just to make amendments during construction.

Suppose a Shop Drawing for your upcoming construction project is as vital as fabrication drawings. In that case, it is suggested that a well-respected shop drawing services provider be hired to create the finest quality shop drawing.

Chudasama Outsourcing performs highly creative drafting and develops good working relationships with the project stakeholders. We have a strict verification procedure in place to eliminate any mistakes from our fabrication drawings.

With a team of experienced designers, architects, and drafters, we are set to provide a complete service to ensure the successful completion of your projects.

Detailed fabrication drawings and professional shop drawing experts of ours show that we are experts in the following: Structural Steel Shop Drawing Services. Are you looking for solutions to your outsourcing needs? Chudasama Outsourcing is here to help. For more information on our services or to set up a complimentary consultation, please reach out to us today!

It takes much more than proper fabrication drawings to ensure the success of the project, and these drawings can make a massive difference to the overall success. It is essential to realize that these drawings serve as the interpretational instrument, which is a critical factor in your achievement.

In Conclusion

Fabrication drawings are a secret weapon use in any construction business, which helps to accomplish the purpose of completing complex designs into physical buildings.

If it wasn’t for their accuracy monitoring, meeting high-quality standards and fulfilling all requirements, there would be no doubt.

The construction experts, along with architecture professionals, do their best by involving different types of fabrication drawings, which can eventually lead to the success of the project. These detailed CAD drawings are the very foundation of cutting-edge construction that helps to create high accuracy and a quicker life cycle.

If you are a construction firm, the time you would need to dedicate to listening to the importance of fabrication drawings and how they can fit particular features of your firm is worth it. By allocating resources to professional drawings, you are supporting your project’s safe and efficient completion in the foreseeable future.

The track from idea to completion is something you need rope skills for, but from the viewpoint of fabrication planning, you can sail it with the accuracy of the master craftsman.